Most Popular Product

|

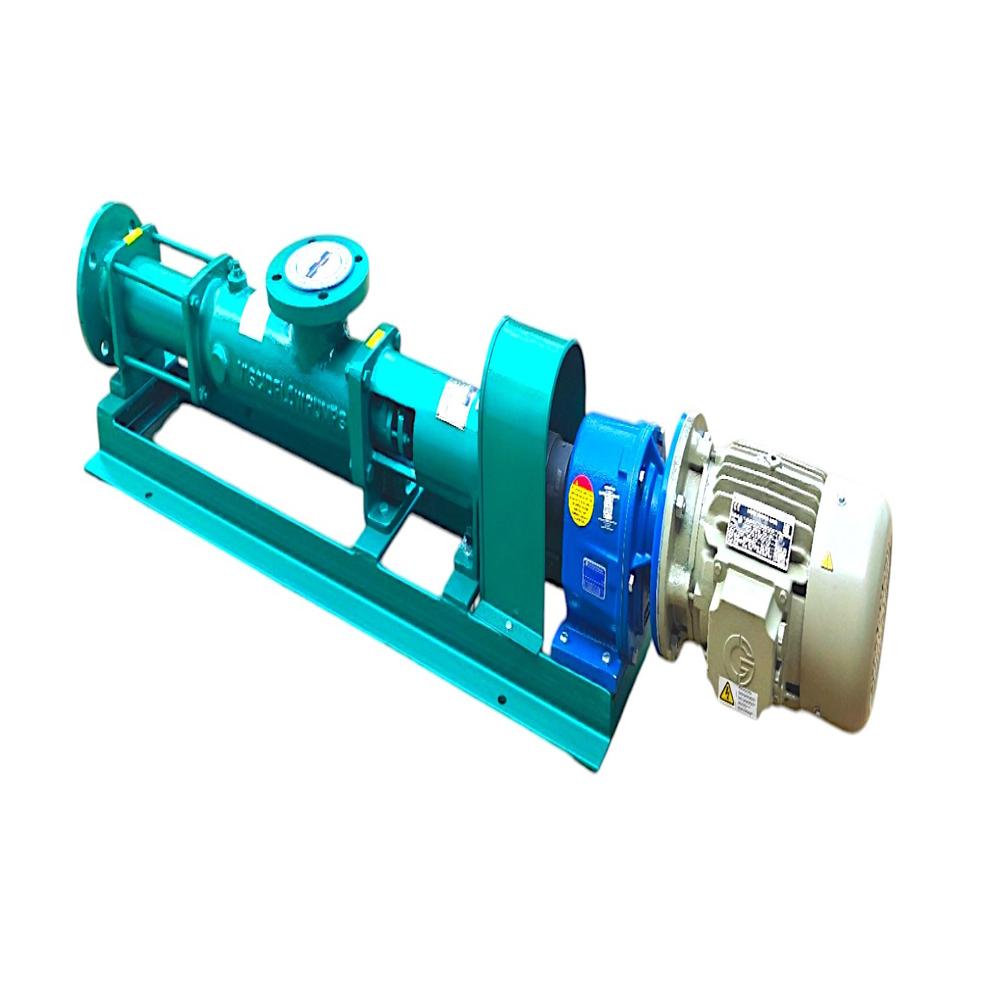

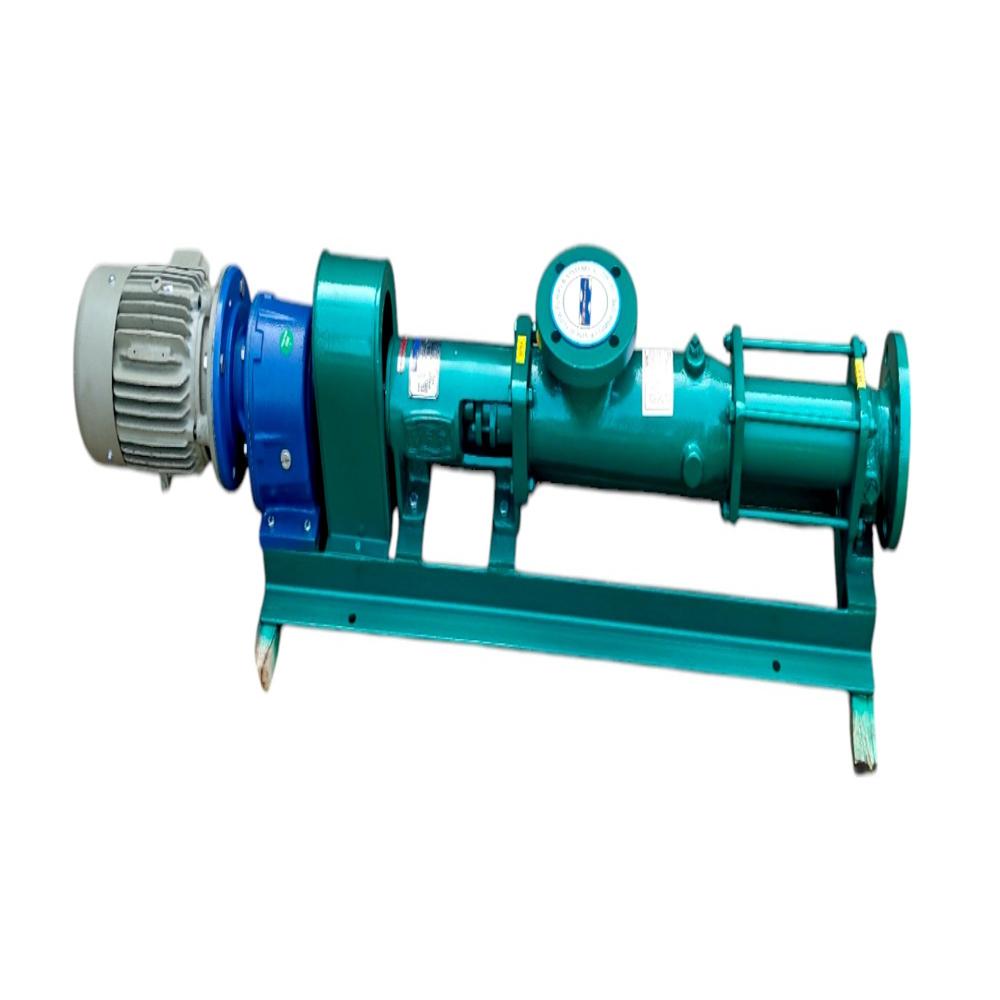

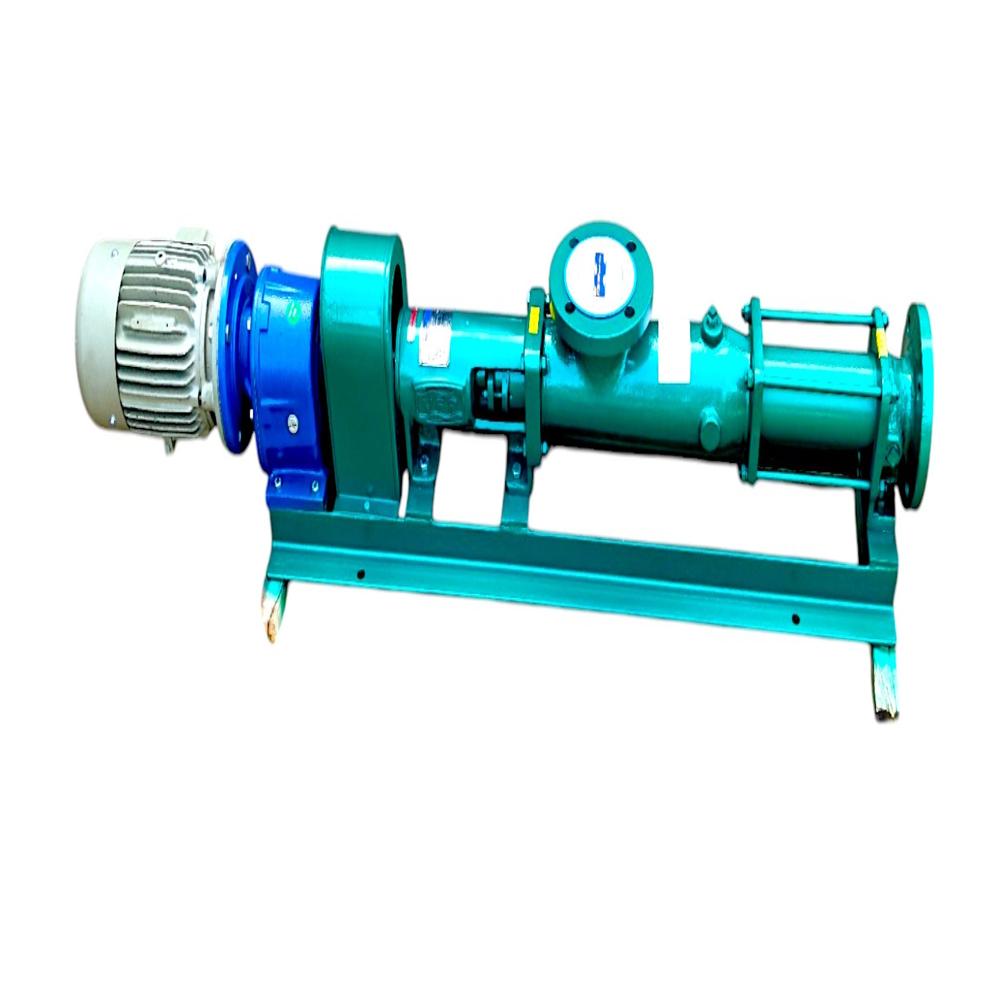

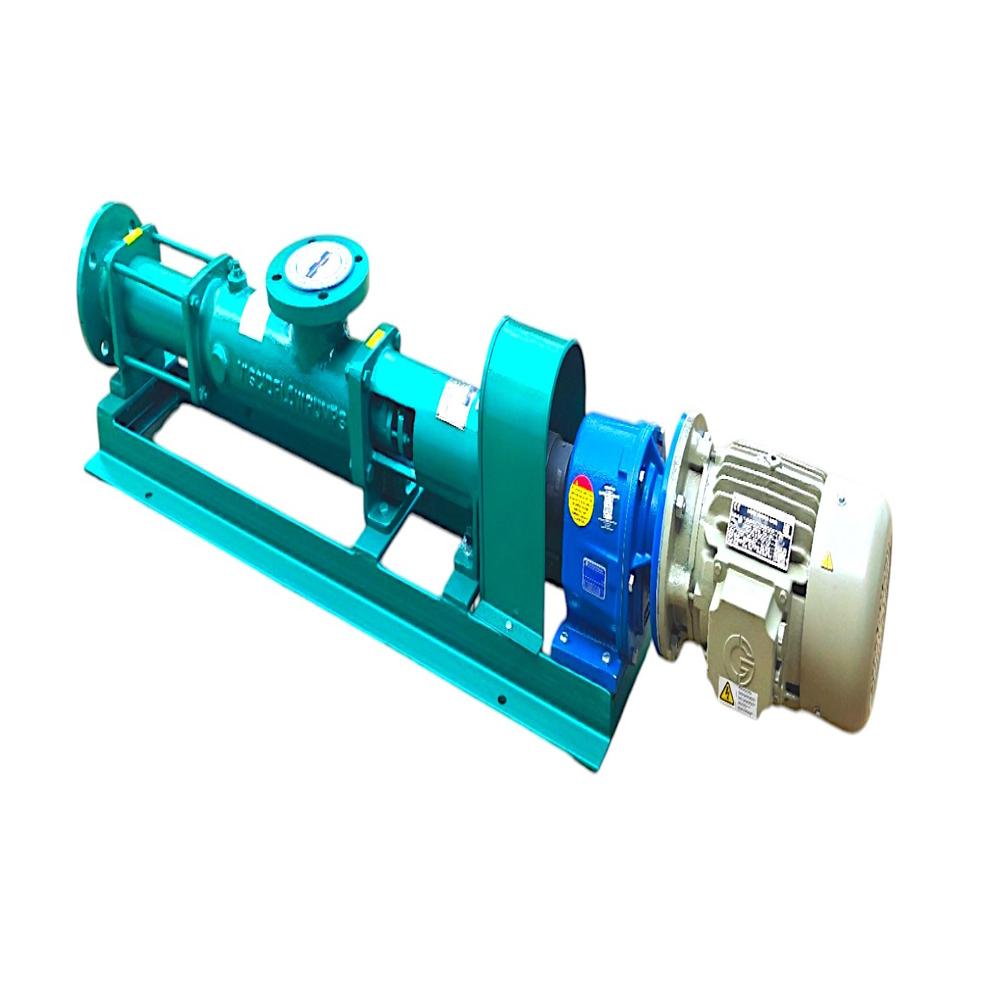

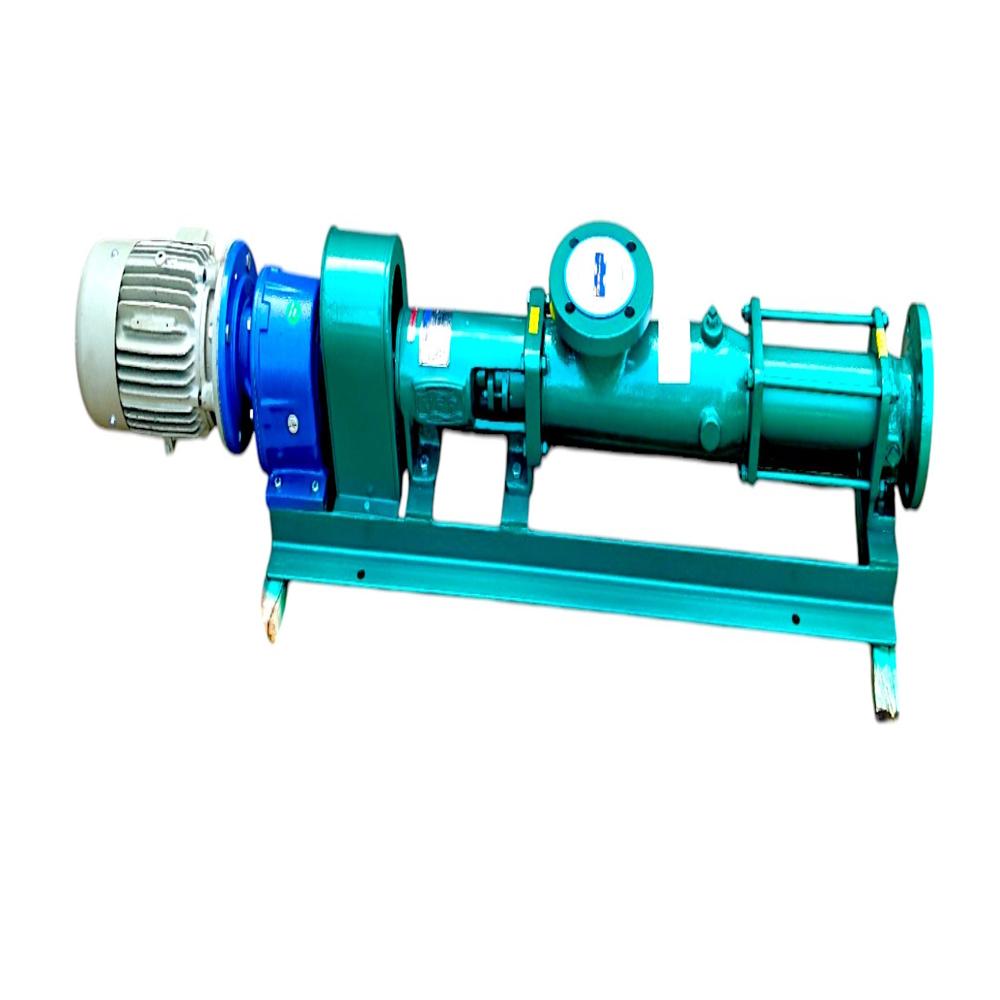

Cast Iron Singe Screw Pump - Helical Rotor SS 316 - For Slurry Transfer

35800.0 INR/Piece

Product Details:

- Discharge Pressure 8 Bar

- Theory Other

- Speed 300 RPM

- Usage ETP, STP , Sewage Water,Raw Sludge,Activated Sludge,Alum Sludge,Centrifuge Sludge & Tannery Effluent

- Mounting Type Horizontal Type

- Frequency 50 Hertz (HZ)

- Flow Rate 15 Tons /Hr

- Click to View more

X

Cast Iron Singe Screw Pump - Helical Rotor SS 316 - For Slurry Transfer Price And Quantity

- 35800.0 INR/Piece

- 1 Piece

Cast Iron Singe Screw Pump - Helical Rotor SS 316 - For Slurry Transfer Product Specifications

- 10 Inch (in)

- Screw pump

- Screw Pump

- 100 Kilograms (kg)

- 25 Inch (in)

- 5 Ampere (amp)

- Progressive Cavity Pump - Helical Rotor SS 316

- 420 Volt (v)

- 4 / 4 [ Inches ]

- 3 Mtrs ( - Ve )

- Self Priming

- ETP, STP , Sewage Water,Raw Sludge,Activated Sludge,Alum Sludge,Centrifuge Sludge & Tannery Effluent

- 300 RPM

- Other

- Gland Packing & Mechanical Seal

- Flooded

- 8 Bar

- Other

- Green

- 80 Celsius (oC)

- Semi - Automatic

- 15 Tons /Hr

- Horizontal Type

- 8 Bar

- 50 Hertz (HZ)

Cast Iron Singe Screw Pump - Helical Rotor SS 316 - For Slurry Transfer Trade Information

- No

- Cash Advance (CA)

- 1 Piece Per Day

- 10 Week

- Yes

- Free samples available with shipping and taxes paid by the buyer

- Wooden Box

- Middle East Africa Australia Central America North America Eastern Europe Western Europe Asia South America

- Central India Kerala Lakshadweep Mizoram Goa Jharkhand Odisha Punjab Assam Arunachal Pradesh Chhattisgarh Sikkim Tamil Nadu Telangana Tripura Pondicherry All India South India West India Gujarat Karnataka Meghalaya Manipur Andhra Pradesh Chandigarh Daman and Diu Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Uttar Pradesh Uttarakhand North India East India West Bengal

- IEC , ISO & Material Test Certificate

Product Description

Progressive cavity pumps excel in slurry applications due to their ability to handle high solids content and viscous fluids without damage or clogging. Their design allows for a smooth, pulsation-free flow, even with abrasive and shear-sensitive materials, making them suitable for industries like mining, wastewater treatment, and food processing.Key Features of Progressive Cavity Pumps in Slurry Applications:Handles high solids content:

Progressive cavity pumps are specifically designed to handle fluids with a significant amount of solids, such as sludges and pastes, without clogging.

Handles viscous and abrasive fluids:The pump's design allows for efficient transfer of viscous and abrasive slurries, common in industries like mining and wastewater treatment.

Pulsation-free flow:Progressive cavity pumps provide a consistent, smooth flow, which is crucial for applications where shear-sensitive fluids are being pumped.

Self-priming capability:Many models can prime themselves, meaning they can handle air entrainment and operate even when the suction line is not fully primed.

Versatility and adaptability:Progressive cavity pumps can be customized for various slurry types and applications, making them adaptable to different industries and processes.

High pumping strength:The pump can generate significant pumping strength, allowing it to handle high pressure and viscosity.

Low NPSH requirements:Progressive cavity pumps generally require lower Net Positive Suction Head (NPSH) compared to centrifugal pumps, making them suitable for applications with limited suction head.

Quiet operation:Progressive cavity pumps are known for their relatively quiet operation compared to other pump types

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

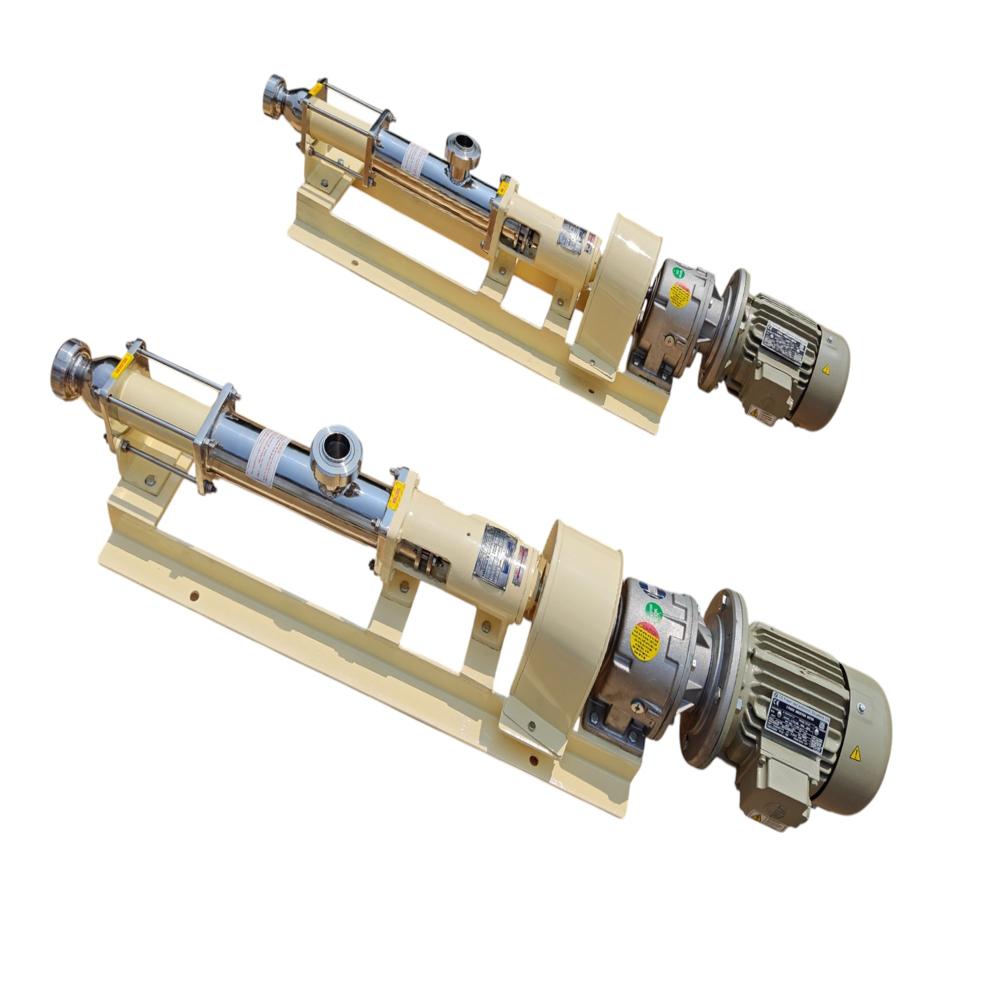

Other Products in 'Screw Pumps' category

|

VISCID FLOW PUMPS AND SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |